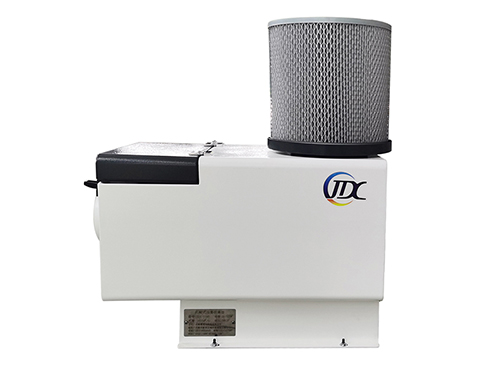

Centrifugal Oil Mist Collector

- High filtering efficiency

- Environmental standards compliant

- Ergonomic design, easy to assembly and maintain

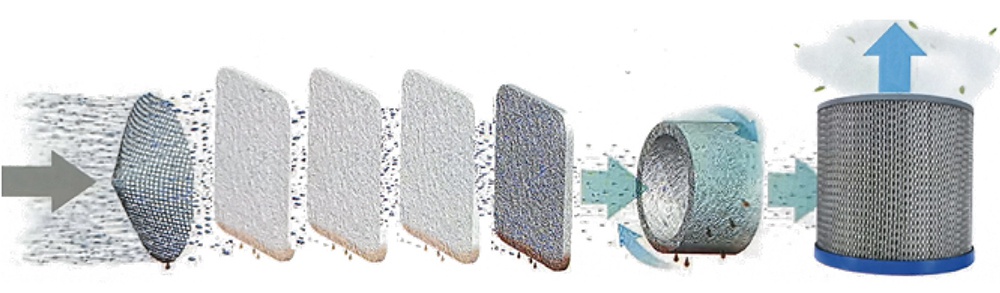

This centrifugal oil mist collector is primarily designed for using on machine tools to collect and filter mist generated from machines, the oil capture efficiency can reach 99%. This oil mist collector adopts multi-stage media to guarantee a high filtration level. The first stage filtration can intercept particles over 10µm, the second stage filtration can catch particles greater than 2µm, while the third stage filtration finishes the air purification by capturing all particles greater than 3µm.

- Common lathe

- CNC lathe

- CNC machining center

- Vertical machining center

- CNC milling machine

- EDM machine

- External cylindrical grinding machine

- Internal cylindrical grinding machine

- High-speed engraving machine

- Drilling & milling machine

- Drilling & tapping machine

- Turning center and more

Power(kW): 0.37

Voltage/Frequency(V/Hz): AC380V/AC220V three phase 50HZ(single phase 220V available)

Speed(rpm): 2800

Flow rate(m³/h): 420-540

Static pressure(kPa) : 0.95

Noise level: 54-56 dB(A)

Inlet(mm): Ф125

Dimensions(L×W×H): 590×305×731

Weight(kg): 35

Power(kW): 0.75

Voltage/Frequency(V/Hz): AC380V/AC220V three phase 50HZ(single phase 220V available)

Speed(rpm): 2800

Flow rate(m³/h): 660-780

Static pressure(kPa) : 1.1

Noise level: 58-60 dB(A)

Inlet(mm): Ф125

Dimensions(L×W×H): 685×360×766

Weight(kg): 40

Power(kW): 1.5

Voltage/Frequency(V/Hz): AC380V/AC220V three phase 50HZ(single phase 220V available)

Speed(rpm): 2800

Flow rate(m³/h): 960-1080

Static pressure(kPa) : 1.7

Noise level: 63-65 dB(A)

Inlet(mm): Ф150

Dimensions(L×W×H): 750×415×848

Weight(kg): 50

Power(kW): 2.2

Voltage/Frequency(V/Hz): AC380V/AC220V three phase 50HZ(single phase 220V available)

Speed(rpm): 2800

Flow rate(m³/h): 1440-1560

Static pressure(kPa) : 2.3

Noise level: 66-68 dB(A)

Inlet(mm): Ф200

Dimensions(L×W×H): 870×460×976

Weight(kg): 70

- Multi-stages of filtration: capturing large-size particles, balancing the airflow;

- Double-row drain ports: oil mist trapped by the collecting unit are discharged from drain ports and into drain collection container for recycling and reuse;

- Flame retardant junction box: thickened enclosure is highly resistant to high temperature and pressure;

- Self-developed fan: featured by large air flow, low noise level, high efficiency filtration and better separation performance;

- External filtering unit: further filtration of small particles and liquid droplets, achieving higher filtration efficiency;

- National standard motor: copper wire totally enclosed motor is adopted, P55 protection and F-rated energy-efficiency, offering excellent stability;

- High-intensity PU ducting: high-temperature resistant, soft, stretchable, and good in tightness;

- Collector base: Reducing the vibration of equipment, and further lowering the noise level;

- First stage interception

- Second stage filtration (reusable filters)

- Third stage centrifugal filtration

- Forth stage small particles filtration

The centrifugal oil mist collector can be equipped with a high efficiency post filter (HEPA) to filter smoke generated during the processing operations.

The surface coating of the machine is subjected to surface treatment process that is commonly used for metal panels of CNC machining center, enabling the mist collector to be easily cleaned without paint fading or peeling.